TM Series

Collaborative Robots

Collaborative robot for assembly, packaging, inspection and logistics

last update: April 11, 2022

OMRON TM Collaborative Robots

OMRON’s line-up of collaborative robots include a variety of models to guarantee the right reach and payload for different applications, including mobile robot compatible (DC) versions.

Designed to meet safety regulations ISO 10218-1

(including TS 15066) and ISO 13849-1.

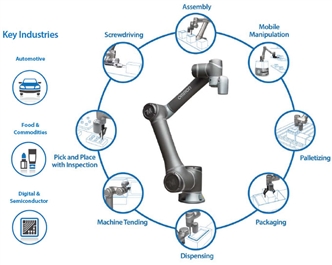

Key Industries & Applications

OMRON TM Collaborative Robots are designed for a wide variety of applications in a number of industries.

Assembly:

Our cobots can improve throughput and consistency of repetitive or complex assembly tasks including part joining, insertion, tool changing, and working alongside people.

Mobile Manipulation:

Mounting an OMRON TM cobot onto an OMRON LD mobile robot, this robotics solution automates not only transportation of goods but also complicated picking operations.

Palletizing:

Our space-saving cobots can streamline end-of-line case stacking onto a pallet. With the Operator Platform, users can build their own palletizing software with a customized interface. OMRON also provides a built-in palletizing wizard in the Operator Platform.

Packaging/Pick and Place with Inspection:

With built-in vision and lighting, our cobots can inspect, sort and pick up products from a conveyor belt before putting them into cases. Customers can quickly adapt production lines to new products or seasonal models.

Machine Tending:

A cobot can be used to tend CNC machines, injection molding machines, stamping and punch pressers, grinding, and cutting machines, relieving workers from repetitive and dangerous work.

Screwdriving:

Our cobots add precision and consistency to your screwdriving and parts fastening applications. A complete ready-to-use solution is provided with a screwdriving kit and pneumatic control box.

Dispensing:

Our cobots add flexibility, efficiency, and freedom to gluing, sealing, painting and other dispensing tasks. Users can record the path using the hand guide and any complex paths can be deployed within minutes.

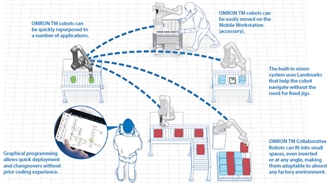

Easy to Use

With graphical programming, hand guiding, and intelligent vision, OMRON TM cobots are designed to be easy and intuitive. Customers can set up simple applications in just a few minutes.

Hand Guide

Hand guide mode allows users to easily set points and assign tasks to the robot. With buttons built into the cobot arm, users can guide the robot into position and automatically record the position in the software.

ISO/TS 15066 Oriented Safety Settings

Our unique patented “body region safety settings” have preset safety parameter values, based on TS 15066 and robot kinematics. There is no need to understand complicated safety calculations to set up a safe application.

Intelligent Vision

Our built-in vision system allows for quick setup of pick-and-place tasks, with the help of easy hand guiding and landmark positioning.

Landmark

A landmark is a physical object that can be recognized by the robot’s built-in camera, and acts as a beacon to help the robot navigate. The robot uses a Landmark as a reference point so it can better locate objects within the workspace.

During high-mix, low-volume production with quick changeovers, customers can redeploy the robot without spending time to recalibrate the vision system.

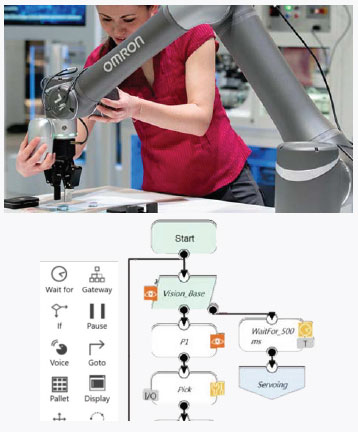

Graphical Programming

Our innovative programming allows users to automate a task with flow-based software, creating full workflows with a click-and-drag method in TMflow. Via Operator Platform, building an application software layout is very intuitive by drag and drop visual elements, no need for trial and error via complex coding.

Designed for Flexible Manufacturing

OMRON TM Collaborative Robots are designed to be easily redeployed to different tasks and applications, making production as flexible as needed.

last update: April 11, 2022